The smart Trick of Premier Aluminum Llc That Nobody is Discussing

The smart Trick of Premier Aluminum Llc That Nobody is Discussing

Blog Article

What Does Premier Aluminum Llc Mean?

Table of ContentsTop Guidelines Of Premier Aluminum LlcGetting The Premier Aluminum Llc To WorkRumored Buzz on Premier Aluminum LlcPremier Aluminum Llc Fundamentals Explained

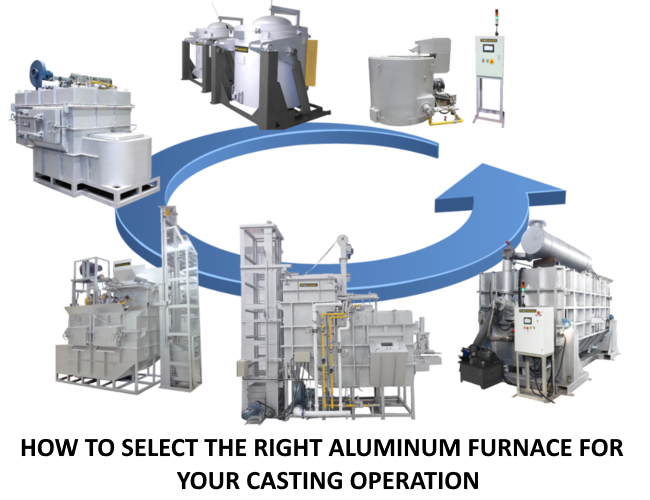

(https://www.merchantcircle.com/premier-aluminum--racine-wi#tips)Traditionally, a purchaser's primary obligation was to discover qualified and receptive distributors. Sometimes, buyers presumed that any type of distributor going to contractually satisfy the acquisition need was certified. Using low cost and unqualified distributors can create quality issues, and squandered time and cash in the lengthy run. To help you via the procedure, below are some points to consider when choosing the best steel casting distributor.

A business that just utilizes the investment spreading process will attempt to sell you on why that procedure is best for your application (Aluminum Metal casting). What if making use of the sand casting process is best for you and your requirements? Instead, seek a supplier that uses a variety of casting processes so the most effective choice for YOU is chosen

If collaborating with a solitary resource for all of your casting needs is essential to you, the vendor needs to be diverse in its capacities. When incorporated with other incorporated capabilities, this can aid simplify and compress the supply base. When picking the best casting supplier, cautious consideration needs to be provided to quality, solution, and price.

The Buzz on Premier Aluminum Llc

Buyers significantly choose spreading providers who have machining capacities. If the casting supplier finds a concern during machining, the trouble is solved quicker with no conflict over whose mistake it is.

What do you require from your casting distributor? Are you looking for someone to just supply a metal component to your doorstep or do you require more?

Some factories are restricted or specialized. Make sure the provider can fulfill all your product or alloy needs to remove the need for numerous suppliers.

The smart Trick of Premier Aluminum Llc That Nobody is Talking About

Research study the provider's internet site. Speak to a sales representative or organization affiliate. Ask a lot of concerns. See their facility. Obtain an understanding of what they can do for you and if you can see on your own developing a strong, shared partnership with them.

Aluminum is also light-weight and has great rust resistance, making it ideal for applications where weight and longevity are vital factors. In addition, aluminum casting is a cost-efficient method of production, as it requires less power and sources than other approaches. Iron spreading, on the other hand, entails pouring molten iron into a mold and mildew to produce a wanted shape.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Iron spreading is additionally able to stand up to high temperatures, making it appropriate for usage in applications such as engine parts and commercial equipment. However, iron spreading can be a lot more pricey than light weight aluminum casting because of the greater price of raw materials and the power called for to melt the iron. When making a decision between aluminum casting and iron spreading, it is very important to consider the details requirements of the application.

In verdict, both aluminum spreading and iron casting have their very own distinct advantages and disadvantages. There are 3 sub-processes that drop under the group of die spreading: gravity die spreading (or permanent mold spreading), low-pressure die casting and high-pressure die casting. To get to the completed item, there are three primary alloys used as die casting material to select from: zinc, light weight aluminum and magnesium. Report this page